Custom Hose Assemblies: What You Need to Know

Custom hose assemblies are essential for hydraulic and industrial systems that require specific configurations to meet unique operational demands. From selecting the right materials to ensuring precise measurements, every detail matters. Here’s what you need to know to create custom hose assemblies tailored to your needs.

1. Understanding Your Application

The first step in creating a custom hose assembly is understanding its purpose and the conditions it will operate under. Key factors to consider include:

- Pressure Requirements: Ensure the hose can handle the system's maximum operating pressure.

- Temperature Range: Choose a hose material that can withstand the environmental and fluid temperatures.

- Media Compatibility: Verify that the hose material is compatible with the fluid being used, such as hydraulic oil, water, or chemicals.

2. Accurate Measurements

Precision is critical when it comes to custom hose assemblies. Improper lengths or fitting angles can lead to inefficiencies or even system failure. To ensure accurate measurements:

- Measure the Hose Length: Account for movement and flex when determining the proper length.

- Determine the Bend Radius: Choose a hose that won’t kink or stress under the system's bend requirements.

- Identify Fitting Angles: Properly align the fittings to ensure a secure connection and avoid leaks.

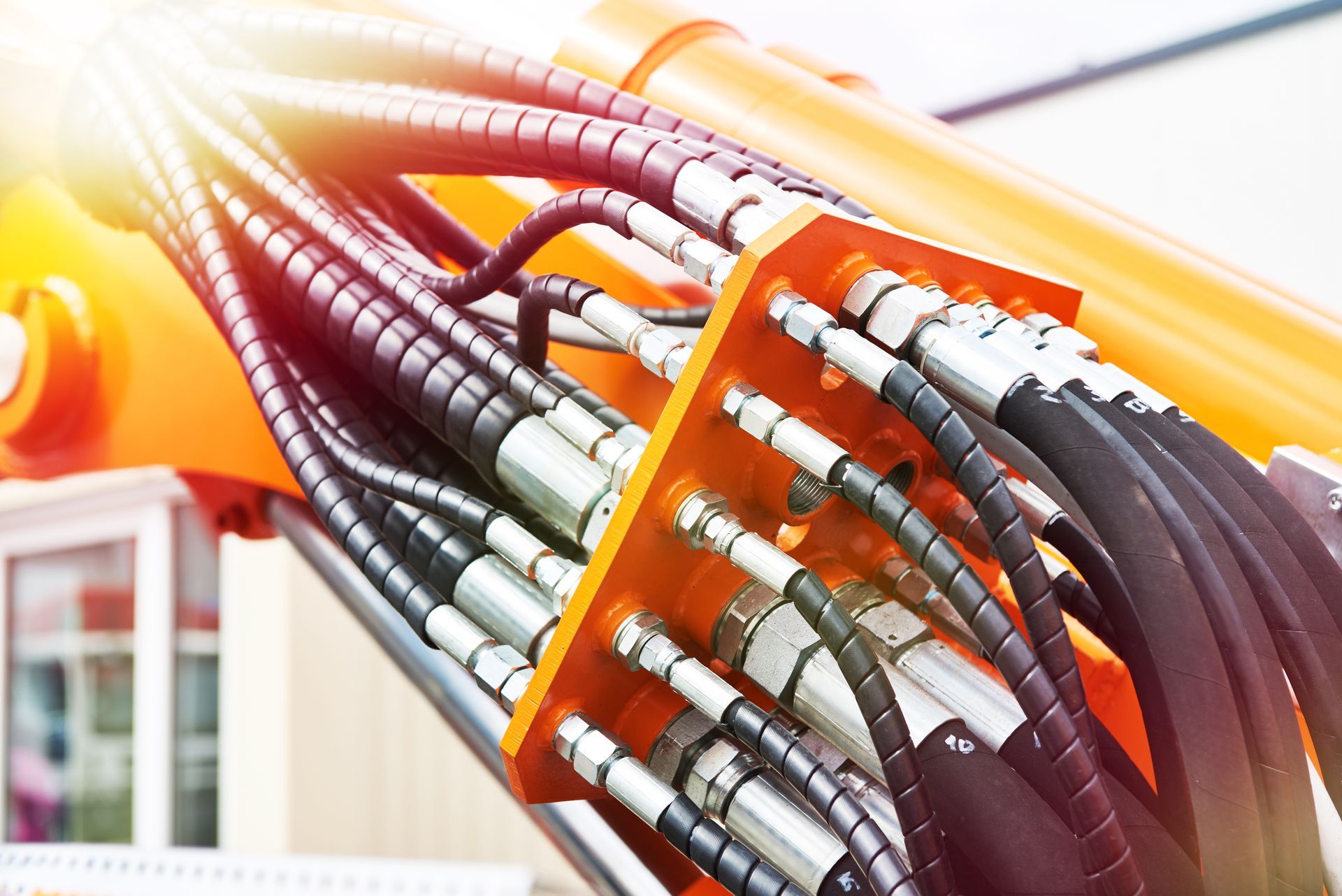

3. Selecting the Right Hose and Fittings

Hoses and fittings must work together seamlessly for a reliable assembly. Common considerations include:

- Hose Material: Options include rubber, thermoplastic, and metal, each suited to specific applications.

- Fitting Types: Select the right threads and connectors, such as NPT, JIC, or BSP, based on your equipment.

- Reinforcement Layers: Determine the number of reinforcement layers needed for added durability in high-pressure systems.

4. Assembly Process

Creating a custom hose assembly involves cutting, crimping, and testing the components to ensure a perfect fit:

- Cutting the Hose: Use precision tools to achieve clean, accurate cuts.

- Crimping the Fittings: Proper crimping ensures a secure connection between the hose and fittings.

- Pressure Testing: Every assembly should be pressure-tested to confirm it meets safety and performance standards.

5. Partnering with Experts

Working with a professional team like Van Otterloo, Inc. ensures your custom hose assembly meets industry standards and your specific requirements. Our experienced technicians can guide you through material selection, design, and installation, offering tailored solutions for any application.

Custom hose assemblies are the backbone of efficient hydraulic and industrial systems. By considering application requirements, choosing the right materials, and ensuring precise assembly, you can maximize performance and reliability. Need a custom solution? Contact Van Otterloo, Inc. today for expert assistance.