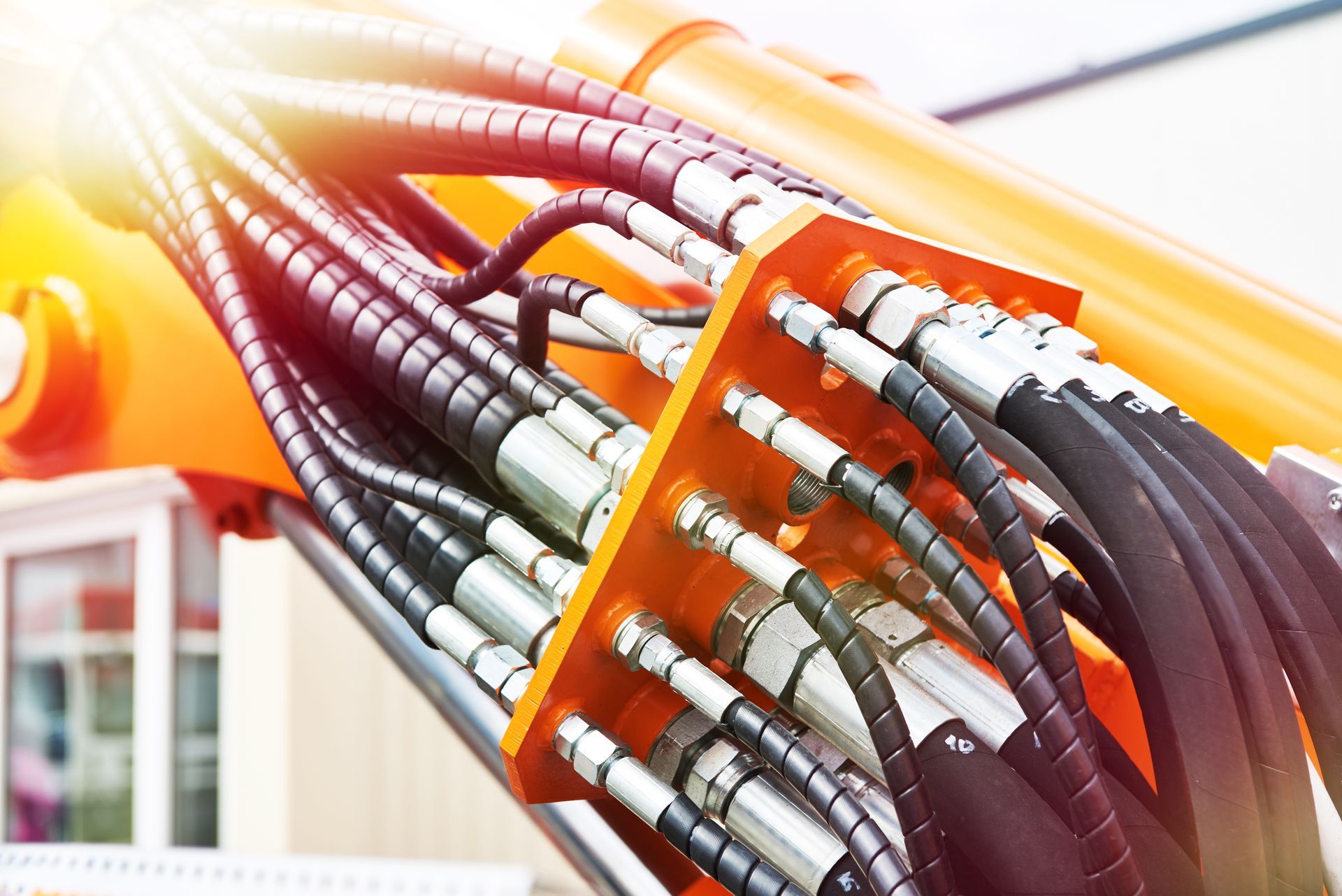

5 Warning Signs Your Hydraulic Hose Needs Replacement

Hydraulic hoses are critical to keeping your equipment running smoothly and safely. Ignoring wear or damage can lead to unexpected failures, costly downtime, and potential safety hazards. Regularly inspecting your hoses and recognizing the early signs of failure can save time and money. Here are five key warning signs that indicate your hydraulic hose might need replacement.

1. Fluid Leaks

One of the most obvious signs of a failing hydraulic hose is fluid leakage. If you notice hydraulic fluid pooling near your equipment or dripping from a hose, it’s likely a sign of cracks, worn-out fittings, or weakened seals. Even minor leaks can reduce system performance and should be addressed immediately to prevent further damage.

2. Cracks or Abrasion on the Outer Cover

Inspect your hoses regularly for visible damage to the outer cover, such as cracks, cuts, or areas where the hose appears worn from rubbing against surfaces. These abrasions can compromise the structural integrity of the hose and may lead to sudden failures under pressure.

3. Bulges or Bubbles

A bulge or bubble on the hose indicates a weakness in its reinforcement layers, often caused by internal damage or high-pressure stress. This is a serious warning sign, as the hose is at risk of rupturing, which could lead to hazardous situations or significant downtime.

4. Reduced Performance

If your equipment isn’t operating at its usual efficiency—such as slower movement, inconsistent pressure, or difficulty maintaining hydraulic functions—it could be due to a partially blocked or damaged hose. Deterioration inside the hose can restrict fluid flow, impacting performance.

5. Age and Service Life

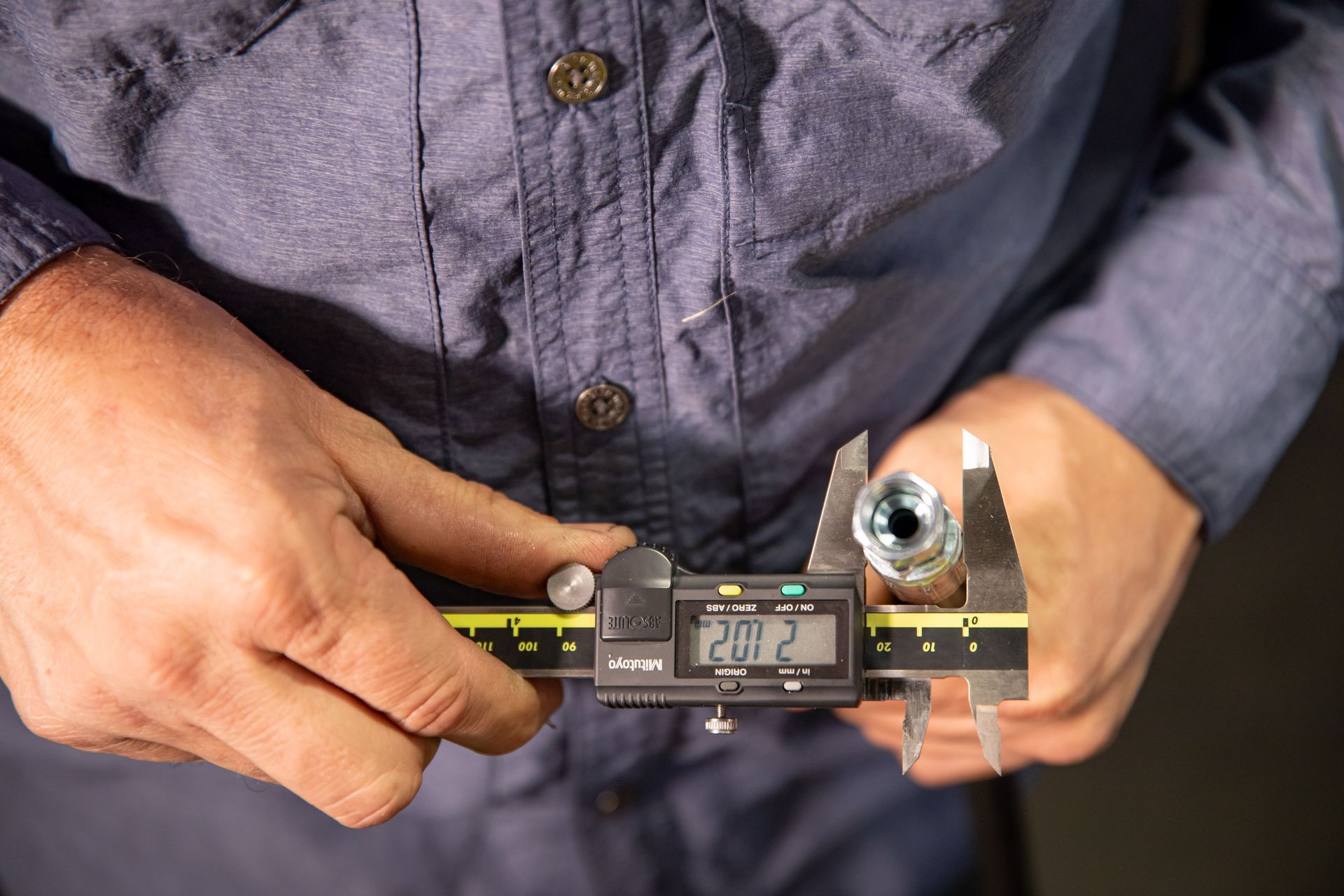

Even if a hose appears in good condition, it’s essential to replace it once it reaches the end of its recommended service life. Over time, the materials degrade due to factors like temperature fluctuations, UV exposure, and regular use, making failure more likely. Refer to your equipment’s maintenance manual or consult a professional to ensure timely replacements.

Preventive Measures to Avoid Failures

To extend the life of your hydraulic hoses and prevent failures:

- Schedule regular inspections to identify wear and tear early.

- Replace hoses proactively rather than waiting for visible signs of damage.

- Ensure proper installation and avoid sharp bends or twists in hoses.

- Use high-quality hoses and fittings suited to your equipment’s specifications.

Recognizing these warning signs and addressing them promptly can help you avoid costly downtime and ensure the safe operation of your equipment. If you need assistance inspecting or replacing your hydraulic hoses, contact Van Otterloo, Inc. today—we’re here to help keep your systems running smoothly and efficiently.