Hydraulic Hose Repair for Heavy Equipment: What Contractors Need to Know

Essential Tips for Construction and Industrial Equipment Operators

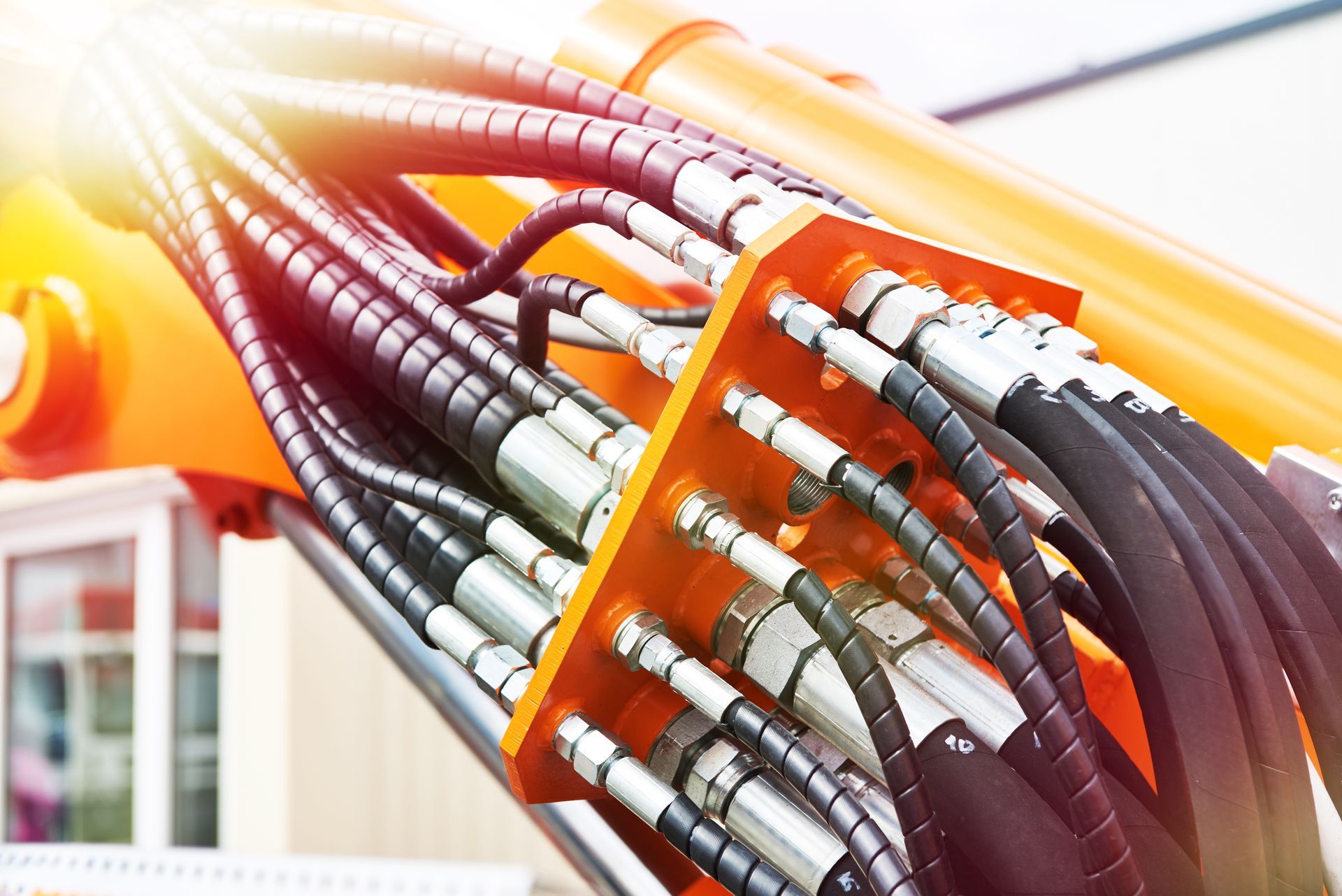

Heavy equipment runs on hydraulic power in construction and industrial settings, from excavators and loaders to backhoes, bulldozers, and cranes. These machines rely on hydraulic hoses to deliver pressurized fluid that powers everything from lifting arms to steering systems

When a hydraulic hose fails, the result is more than just downtime, a delay in your project, a strain on your budget, and a risk to your team’s safety. That’s why every contractor and operator should know how to spot early warning signs, minimize downtime, and handle repairs properly.

1. Know the Common Causes of Hydraulic Hose Failure

Heavy equipment is exposed to some of the most extreme conditions on a jobsite. Hoses are frequently subjected to:

- High-pressure cycles

- Extreme heat and cold

- Constant vibration and movement

- Dust, debris, and chemical exposure

These factors contribute to wear and tear, increasing the risk of:

- Cracking and abrasions

- Fluid leaks

- Blisters or bulging hoses

- Loose or corroded fittings

- Burst hoses

Tip: Most hydraulic hose failures are progressive, not sudden. Catching them early is key to preventing a full-blown breakdown.

2. Inspect Equipment Daily

Construction sites are fast-paced environments, but taking a few minutes for a pre-shift inspection can save hours of downtime later.

What to check:

- Leaks around hose fittings or connections

- Visible wear, cracks, or bulges on the hose body

- Hoses rubbing against other components

- Kinks, twists, or flattened areas

- Fittings that feel loose or corroded

Tip: Make hose inspection part of your daily walk-around checklist before starting any machine.

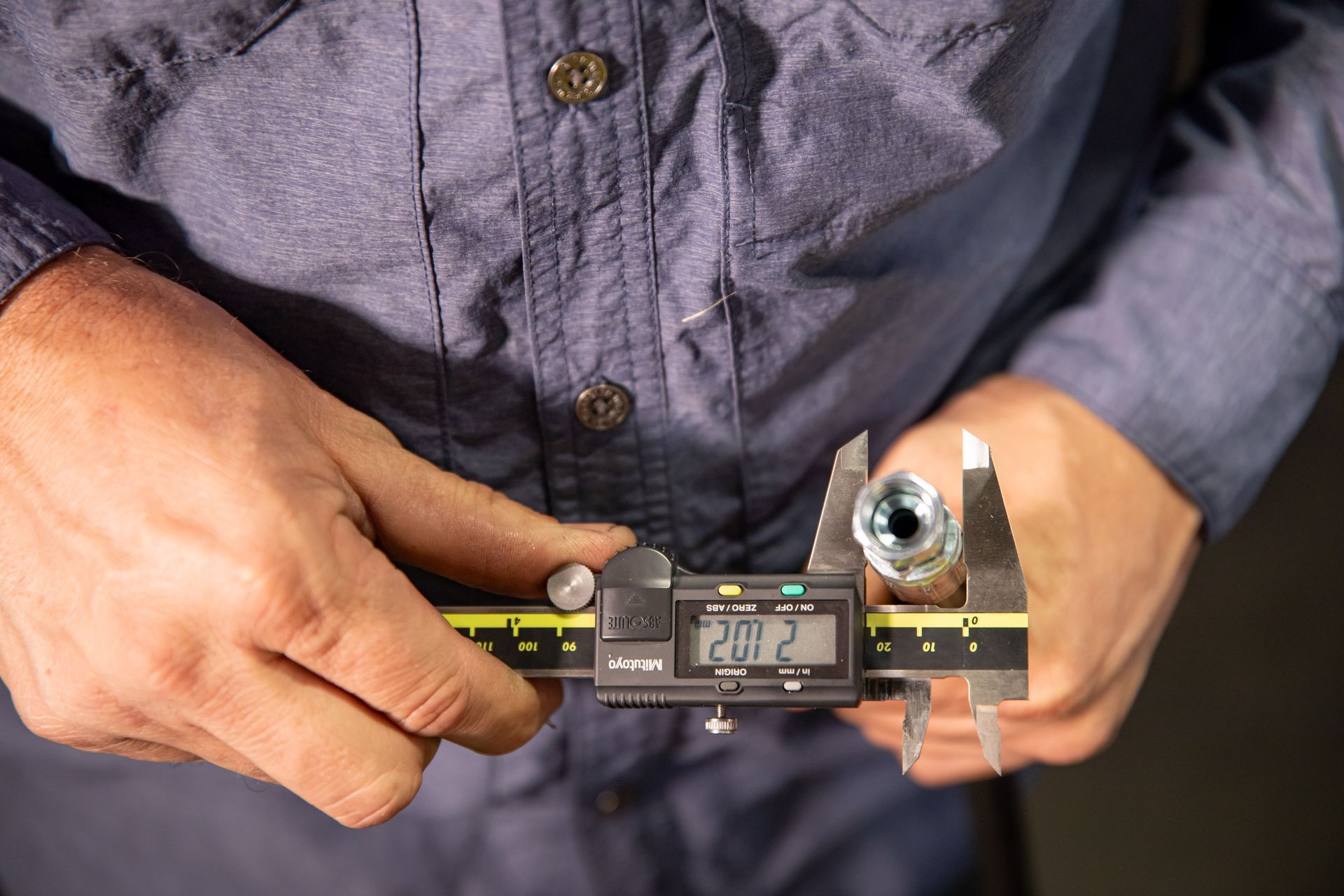

3. Understand the Right Hose for the Job

Not all hydraulic hoses are created equal. Choosing the wrong hose can lead to premature failure, especially in heavy-duty applications.

Factors to consider:

- Pressure rating – Must match or exceed your equipment’s system pressure

- Temperature rating – Account for ambient heat and hydraulic fluid temps

- Material compatibility – Ensure the hose is compatible with the type of hydraulic fluid used

- Flexibility & routing – Hoses should bend without kinking and fit neatly within the equipment layout

Tip: Work with a professional hose technician to spec the proper hose for your equipment and jobsite conditions.

4. Respond Quickly to Leaks and Damage

If you notice a hydraulic fluid leak or a damaged hose, shut down the equipment immediately. Running machinery with a compromised hose can:

- Increase damage to pumps or cylinders

- Cause catastrophic hose bursts

- Put your crew in danger from high-pressure fluid

Tip: Don’t try to patch or “get by” with a quick fix; temporary solutions can be dangerous and cost more in the long run.

5. Use On-Site Hose Repair to Avoid Downtime

When a hose fails, traditional repairs often mean:

- Removing the hose

- Driving to a repair shop

- Waiting for a replacement

- Reinstalling the hose hours or days later

That kind of delay is costly, especially on tight project deadlines.

Why On-Site Repair Makes Sense:

- A technician comes to your jobsite

- Hoses are repaired or replaced immediately

- Custom hoses are built on the spot

- Your equipment is back in action in hours, not days

Tip: Partner with a trusted mobile hydraulic hose repair provider to avoid scrambling when things go wrong.

6. Stay on Top of Preventive Maintenance

Heavy equipment operates under harsh conditions, so proactive maintenance is non-negotiable. Schedule regular hose inspections and replacements based on:

- Equipment age and service hours

- Operating pressure and cycles

- Environmental exposure

Tip: Replacing hoses on a schedule (not just when they fail) helps avoid project-stopping surprises and keeps your equipment reliable.

Protect Your Projects, Keep Your Hoses in Check

As a contractor, you’ve got deadlines to hit, crews to manage, and equipment to rely on. One failed hydraulic hose can throw off your entire operation. But with the proper knowledge, tools, and support, you can prevent breakdowns, minimize downtime, and keep your jobsite moving forward.

Need Immediate Hydraulic Hose Repair in San Diego?

At Van Otterloo Inc., we specialize in on-site hydraulic and industrial hose repair and replacement for construction and industrial equipment. Our mobile technicians come to your jobsite fully equipped to inspect, replace, and install hoses on demand.

Get your heavy equipment back to work, fast, safe, and reliable.