Emergency Hydraulic Hose Repairs: What to Do When a Hose Fails

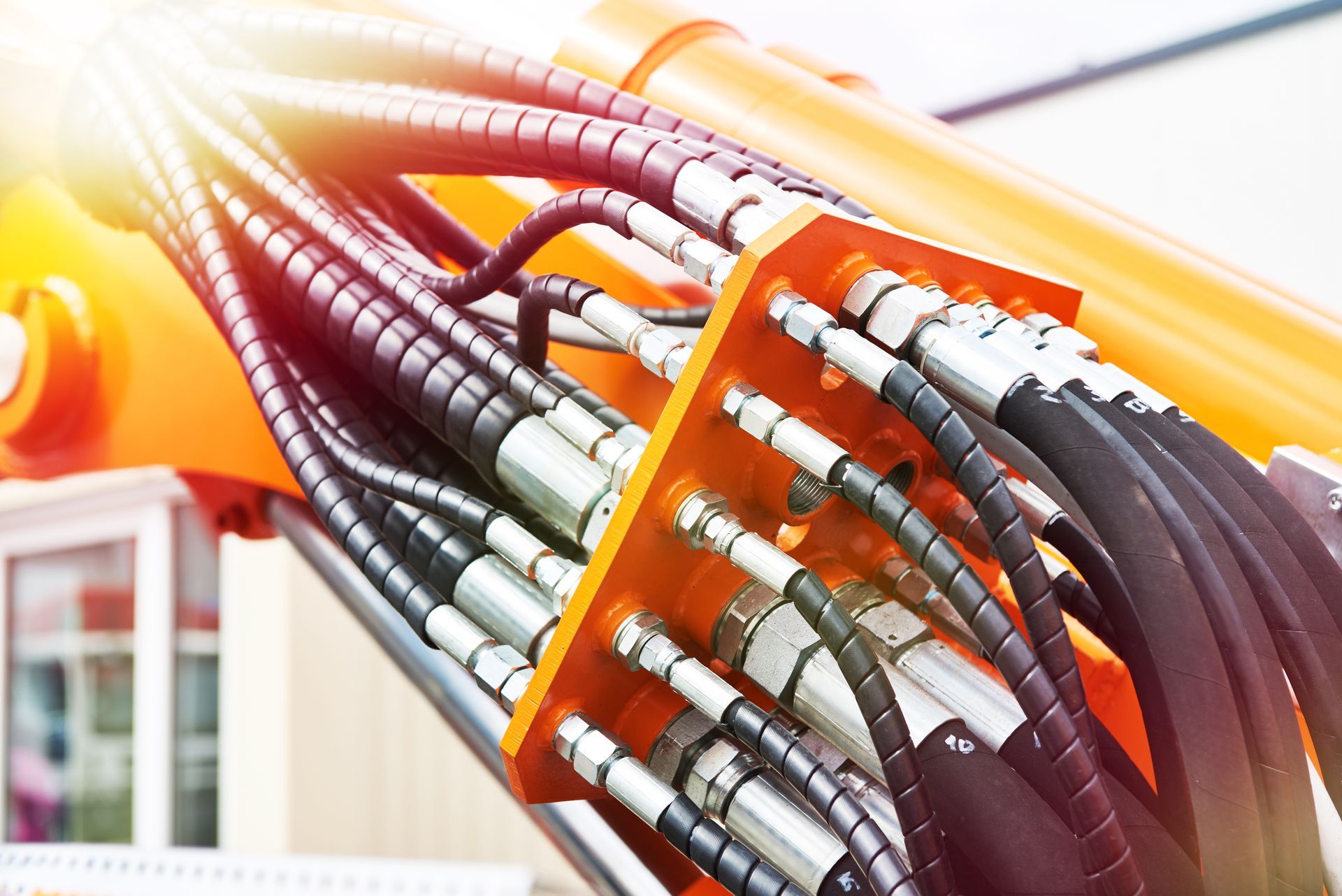

Hydraulic systems are essential in keeping equipment and machinery running smoothly. A sudden hydraulic hose failure can halt operations, cause costly downtime, and even create safety hazards. Understanding how to respond quickly and effectively is critical for fleet managers, operators, and maintenance teams.

Recognizing a Hydraulic Hose Failure

Hydraulic hose issues can develop gradually, but some failures happen unexpectedly. Common signs include:

- Visible leaks of hydraulic fluid

- Hissing or unusual noises from pressurized lines

- Decreased performance or sluggish equipment response

- Swelling, cracking, or fraying of hoses

Immediate action is crucial to prevent further damage to the system and maintain workplace safety.

Step 1: Ensure Safety First

Safety is the top priority during any hydraulic failure.

- Shut down the equipment immediately to stop fluid flow.

- Relieve system pressure according to manufacturer guidelines to prevent accidents.

- Wear protective gear such as gloves and safety glasses to protect against high-pressure fluid leaks.

Keep bystanders at a safe distance to avoid injuries from pressurized spray.

Step 2: Assess the Damage

Once the system is safely powered down, inspect the hose and surrounding components. Determine whether the hose can be repaired temporarily or if it needs a full replacement. Look for:

- Cracks, frays, or ruptures

- Leaks at fittings or connections

- Kinks or twisting that may have caused wear

Documenting the damage is also helpful for maintenance records and warranty purposes.

Step 3: Apply a Temporary Fix (If Safe)

In some cases, temporary repairs may allow limited operation until a full replacement can be performed. Common temporary measures include:

- Using

hose clamps or sleeves to reduce leaks

- Wrapping the hose with

specialized tape designed for hydraulic applications

Always follow manufacturer recommendations and ensure that temporary fixes do not compromise safety. Temporary repairs are only meant to provide short-term relief.

Step 4: Replace the Hose Properly

A permanent solution requires a full replacement of the failed hydraulic hose. Steps include:

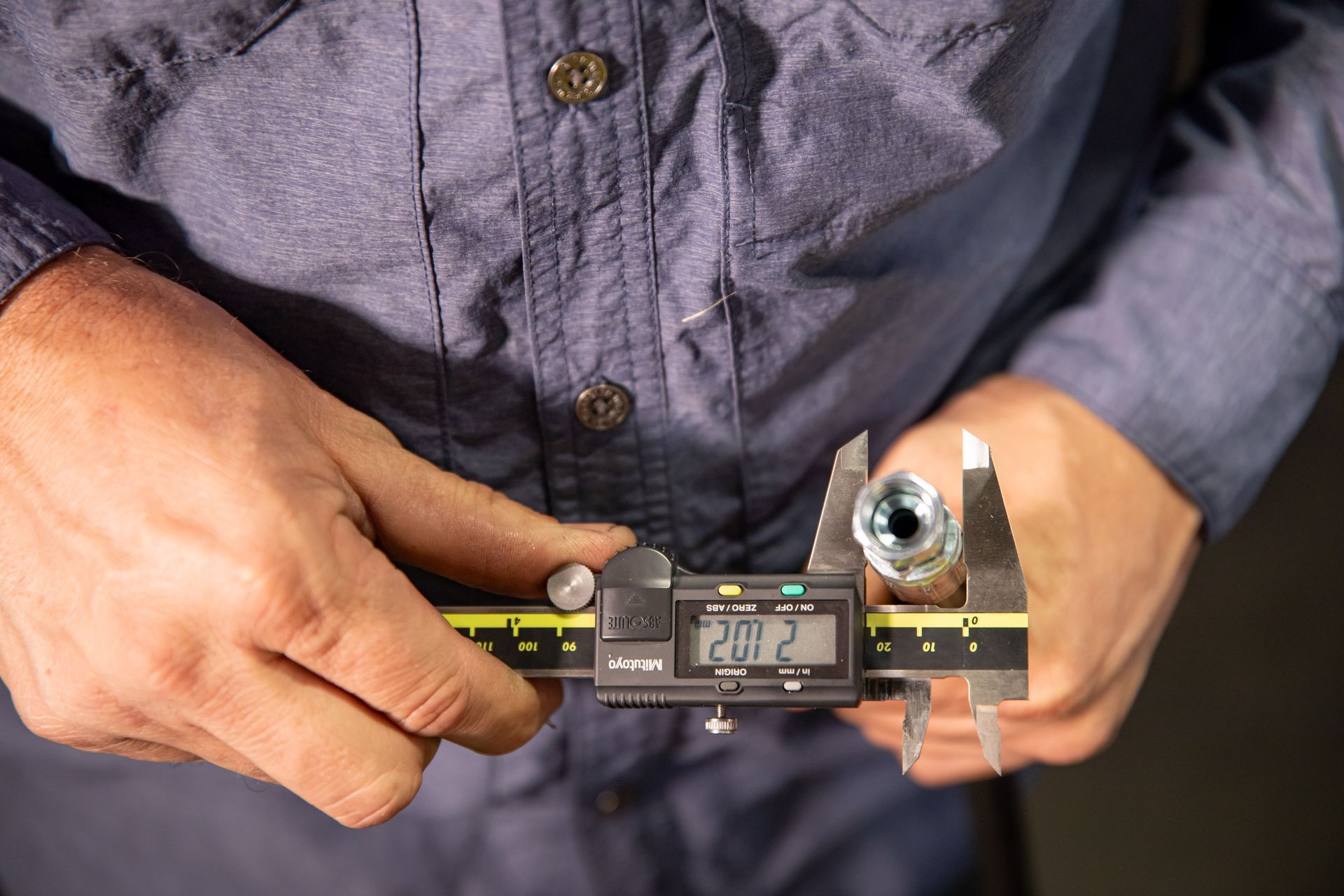

- Select the correct hose type and size to match system specifications.

- Disconnect fittings carefully, ensuring all pressure is relieved.

- Install the new hose, avoiding kinks or sharp bends.

- Secure fittings and test the system for leaks before returning to full operation.

Proper installation ensures the longevity of the hose and prevents recurring failures.

Step 5: Prevent Future Failures

Proactive maintenance reduces the likelihood of emergency hydraulic failures. Consider:

- Regular inspections of hoses and fittings

- Replacing hoses on a scheduled basis before wear becomes critical

- Training operators to recognize early warning signs of hydraulic issues

- Keeping spare hoses on hand for rapid replacement

Preventive care not only improves safety but also minimizes downtime and repair costs.

Partner with Van Otterloo Inc. and Take Action

Hydraulic hose failures can disrupt operations, but the right expertise and resources make all the difference. Van Otterloo Inc. provides fast, reliable hydraulic hose repair and replacement services to keep your fleet and equipment operational. Our experienced team can help with emergency repairs, routine maintenance, and system assessments to prevent costly failures.

Do not let a hydraulic hose failure bring your operations to a halt. Contact us for professional emergency hydraulic hose repairs and preventative maintenance solutions. Ensure your equipment runs safely and efficiently, every day.