The Importance of Preventive Maintenance in Reducing Downtime

When it comes to hydraulic and industrial equipment, a proactive approach to maintenance can mean the difference between smooth operations and costly disruptions. Preventive maintenance, particularly for hydraulic hoses, is an essential strategy to avoid unexpected failures, extend equipment life, and save money over time. Here’s why prioritizing this practice is crucial for your business.

1. Minimizing Unexpected Downtime

Equipment breakdowns can bring operations to a halt, delaying projects and increasing costs. Preventive maintenance involves regular inspections to identify wear, leaks, or damage in hydraulic hoses before they lead to failure. By addressing these issues early, you can prevent unscheduled downtime and keep your workflow uninterrupted.

2. Enhancing Safety

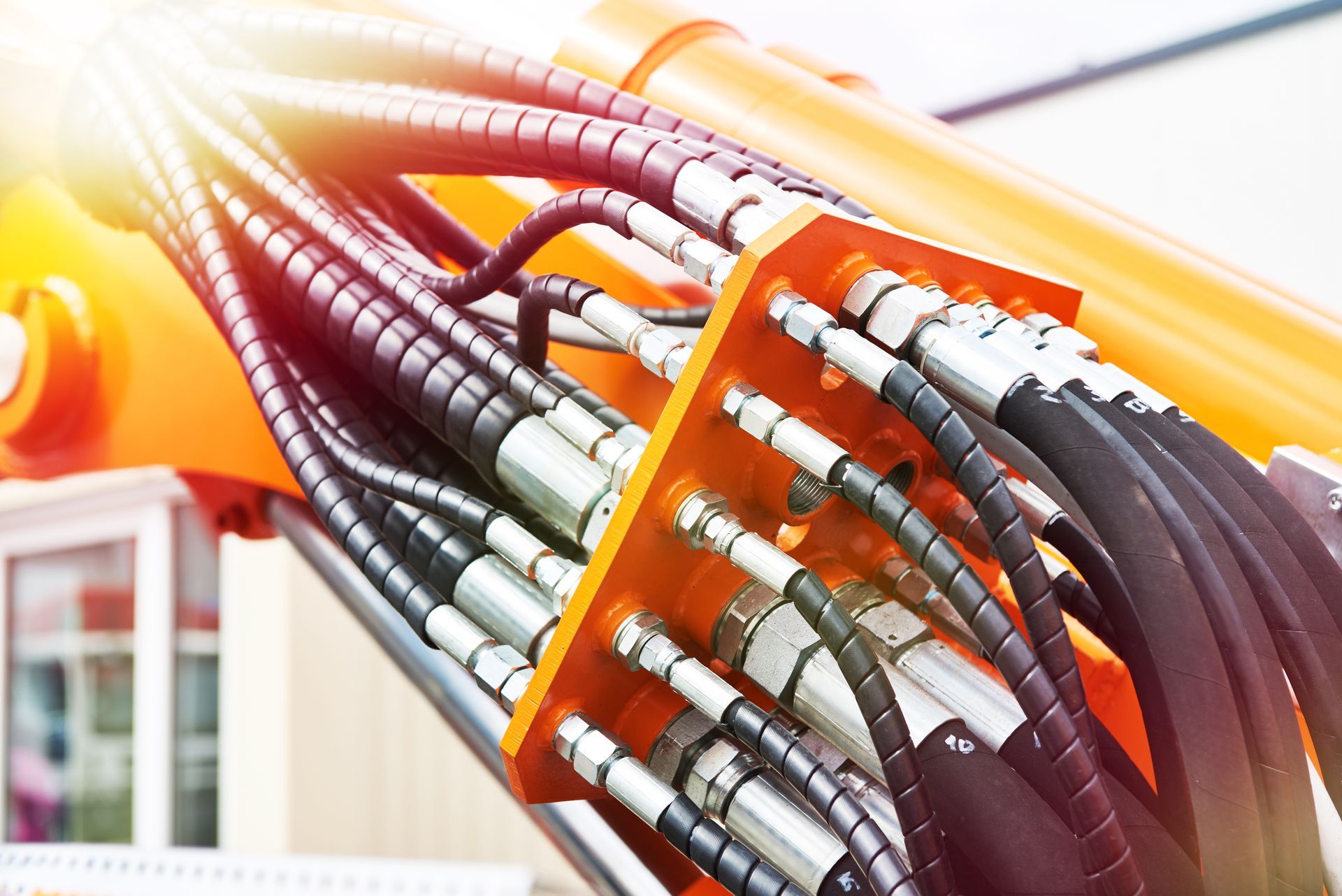

Hydraulic systems operate under high pressure, and a sudden hose failure can pose serious safety risks to workers and equipment. Preventive maintenance reduces the likelihood of accidents by ensuring hoses, fittings, and connections are in top condition. This proactive approach fosters a safer work environment and protects your team from avoidable hazards.

3. Reducing Long-Term Costs

While maintenance might seem like an added expense, it’s far less costly than repairing or replacing damaged equipment after a failure. Scheduled inspections and proactive replacements prevent secondary damage caused by leaking hydraulic fluids, such as equipment corrosion or contamination. Investing in maintenance now saves you from expensive repairs later.

4. Extending Equipment Lifespan

Hydraulic hoses are a critical component of your equipment, and their performance directly impacts the longevity of the machinery they support. Preventive maintenance ensures that hoses and related parts are functioning optimally, reducing strain on other components and helping your equipment operate efficiently for longer.

5. Improving Productivity

Efficient equipment leads to increased productivity, and preventive maintenance ensures that your systems are always ready to perform. Instead of dealing with delays caused by unplanned repairs, your team can focus on meeting deadlines and achieving goals without interruptions.

How to Implement Preventive Maintenance

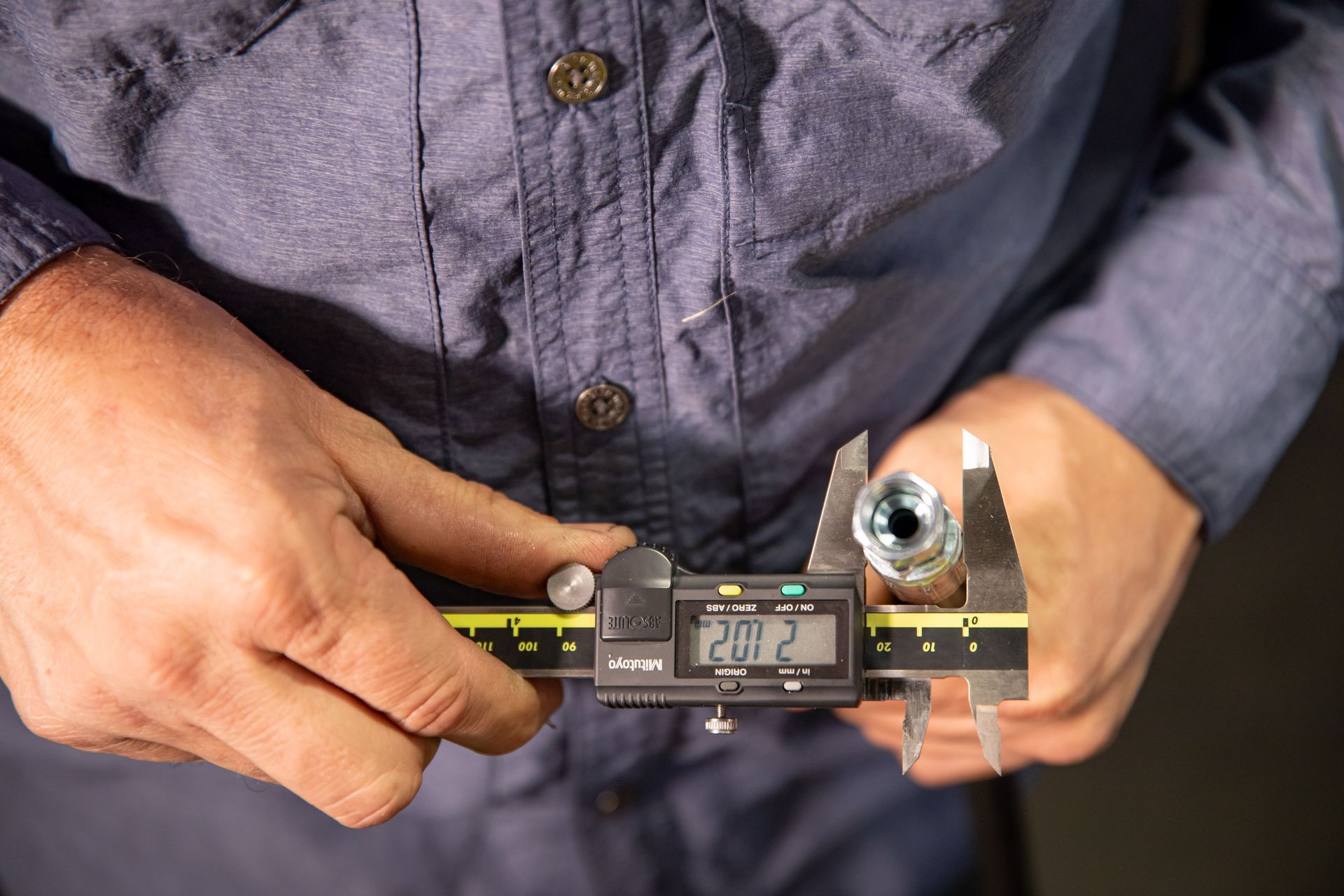

- Schedule Regular Inspections: Check hoses for signs of wear, such as cracks, leaks, or abrasion, and inspect fittings for tightness and corrosion.

- Document Maintenance Activities: Keep a log of inspections, repairs, and replacements to identify recurring issues and establish maintenance patterns.

- Replace Hoses Proactively: Don’t wait for a hose to fail; replace it when signs of deterioration are evident or when it reaches its recommended service life.

- Partner with Experts: Work with a reliable provider like Van Otterloo, Inc., who can assist with inspections, repairs, and replacements tailored to your equipment’s needs.

By making preventive maintenance a priority, you’re not only protecting your equipment but also enhancing your business’s bottom line. A small investment in care today can prevent significant disruptions tomorrow. Contact Van Otterloo, Inc. to learn how our maintenance services can keep your hydraulic systems running smoothly and efficiently.