Keep Your Fleet Moving: The Critical Role of Hydraulic Hose Inspections

The Importance of Hydraulic Hose Inspections for Fleets

Fleet owners understand that vehicle and equipment uptime is critical. Whether managing trucks, tractors, or industrial machinery, one unexpected hydraulic failure can lead to costly downtime, missed deadlines, and expensive repairs.

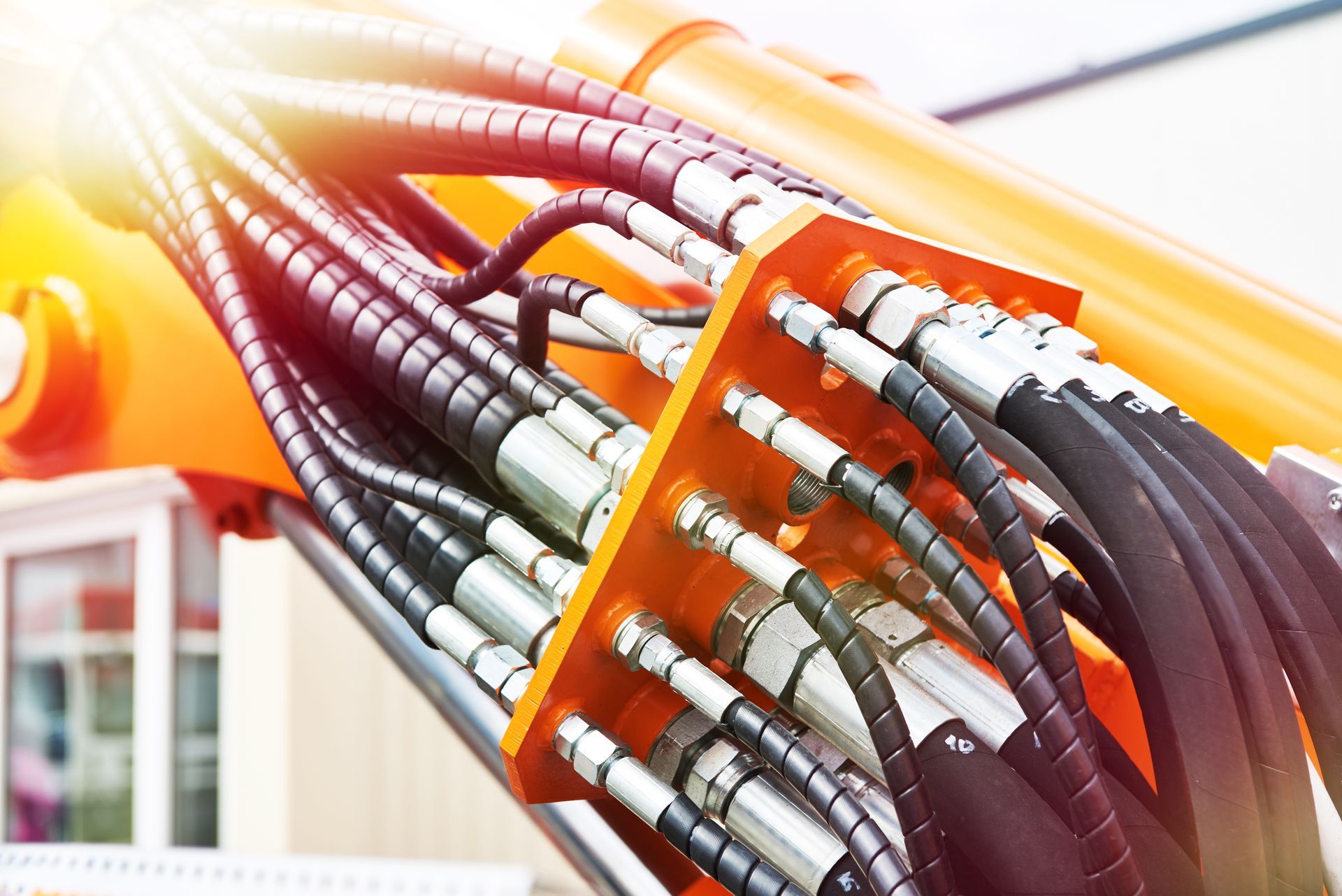

Hydraulic hoses may seem like small components, but they play a vital role in system performance. Regular inspections ensure hoses are in top condition, preventing leaks, failures, and unsafe operating conditions.

1. Prevent Costly Breakdowns

Hydraulic hose failures often occur suddenly and without warning. A burst hose can stop a vehicle or piece of equipment in its tracks, leading to:

- Lost productivity

- Emergency repair costs

- Potential damage to surrounding components

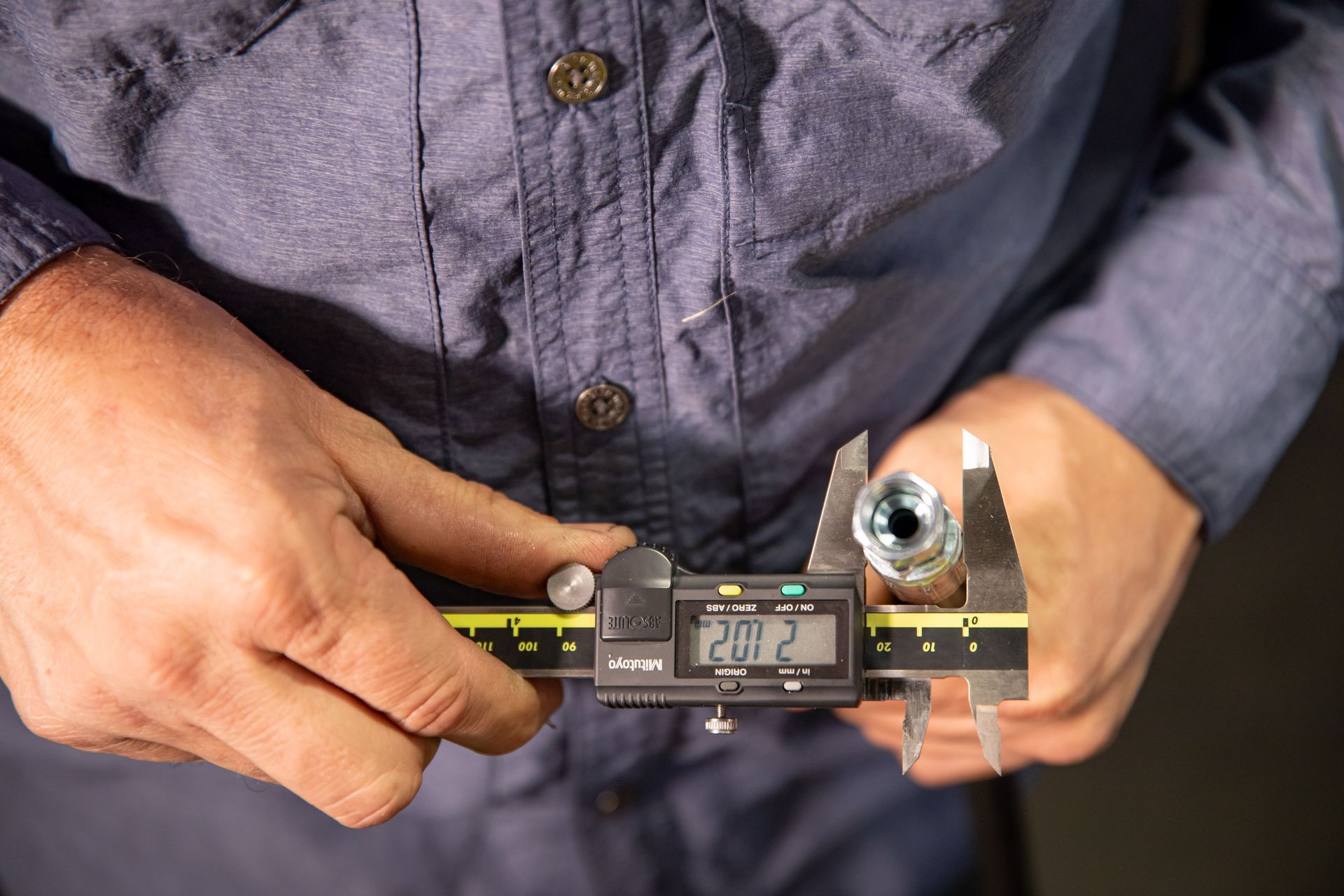

By performing regular inspections, fleet owners can identify signs of wear—such as cracking, bulging, or abrasion—before they escalate into costly failures.

2. Ensure Safety for Operators and Equipment

A failing hydraulic hose is not just a maintenance issue; it is a safety hazard. High-pressure fluid leaks can cause injuries, fires, or environmental spills. Fleet operators rely on inspections to detect early warning signs:

- Visible leaks

- Excessive vibration

- Unusual noises during operation

Routine inspections reduce risks to employees, protect equipment, and help fleets maintain a strong safety record.

3. Maximize Equipment Lifespan

Hydraulic systems are designed to work with precision. Worn or damaged hoses reduce efficiency and place extra strain on pumps, cylinders, and fittings. Regular inspections and replacements:

- Maintain proper fluid pressure

- Reduce unnecessary wear on other components

- Extend overall system and equipment lifespan

Fleet owners who schedule inspections see fewer breakdowns and longer-lasting equipment, providing significant long-term savings.

4. Minimize Operational Downtime

Downtime can be extremely costly in fleet operations. Unscheduled repairs can lead to missed deadlines, decreased productivity, and dissatisfied clients. A proactive inspection program allows fleet managers to:

- Identify hoses near the end of their service life

- Replace them during planned maintenance windows

- Keep vehicles and equipment operational without interruption

Regular inspections keep your fleet running smoothly and minimize unexpected disruptions.

5. How Van Otterloo Inc. Can Help

At Van Otterloo Inc., we specialize in hydraulic hose solutions for fleet and industrial applications. Our experienced technicians provide:

- On-site inspections of hoses, fittings, and related components

- Preventive maintenance programs tailored to fleet schedules

- Emergency repairs to minimize downtime

- Guidance on proper hose selection, routing, and storage

By partnering with Van Otterloo Inc., fleet owners gain a trusted resource that helps protect their equipment, maintain efficiency, and ensure operator safety.

Take a Proactive Approach to Fleet Maintenance

Hydraulic hoses are small components, but their impact on fleet operations is significant. Prioritizing regular inspections:

- Prevents costly failures

- Enhances safety

- Extends equipment life

- Minimizes downtime

Van Otterloo Inc. is here to help fleet owners implement an inspection and maintenance program that keeps vehicles and equipment running at peak performance.

Call Van Otterloo Inc. today to schedule a hydraulic hose inspection and ensure your fleet stays operational, efficient, and safe.